Defrost Room that minimizes dripping /

Rapid Cold Storage Room capable of cooling

high-temperature products.

Can provide cold storage after defrosting.

Improves product quality and yield rate.

The inside of the room can be washed by CIP,

enabling excellent hygiene.

Boxed fish

Boxed beef

Boxed chicken

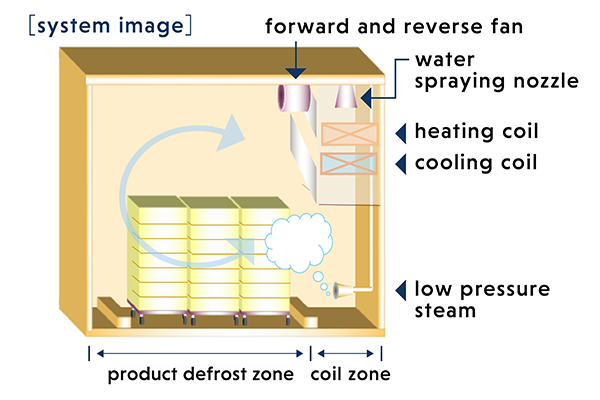

The circulation fan uses air flow control and inverter operation to reduce uneven defrosting.

Also, temperature control at +10℃ or less minimizes product burns and discoloration. This defrosting method uses

condensing latent heat so that the temperature difference between product surface and core is minimal,

thus reducing drip loss compared to conventional defrosting methods.

Humidification is conducted by steam, which is more hygienic than water-spraying.

The interior temperature is controlled to be +10℃ or less while defrosting to prevent microbial growth.

The simple structure has a low ceiling and the cooling/heating coil zone is installed on the side for better

washability. The water-resistant material finish makes it possible to wash whole.

Cooling and heating coils were removed from the casing to reduce cost. With the touch-panel control board that

is simple to operate, product temperature status and interior temperature can be checked at a glance and

defrosting operation progress can also be confirmed with the trend graph. In anticipation of future changes,

we made it possible to set a wide range of defrosting patterns according to product purpose and defrosting

temperature, etc.

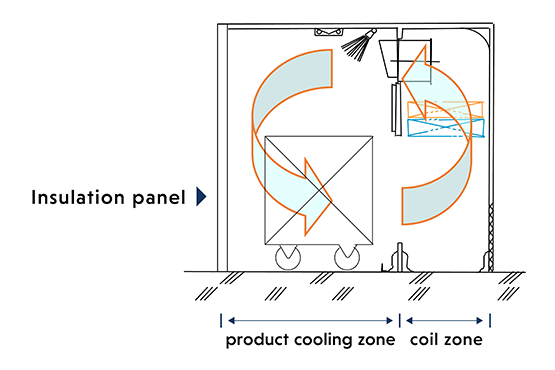

The simple structure that has no cooler casing enables CIP washing of the cooler. The cooler zone can be entered from the inspection door, so it is simple to check after washing and sterilizing the path of cold winds that serves as blinds and also to conduct maintenance-inspection and manual cleaning. Also, the cooler zone is separated to the side in the room, thus the product chilling zone can be kept sanitary with no impact from drainage and defrosted water. The ceiling can be lowered, making it possible to wash all of the inside.

Operation is all done with the color touch panel. There is nothing complicated and anyone can operate this easily.

In anticipation of future changes, we made it possible to set a wide range of chilling patterns according to

product type and chilling temperature, etc.